This is a transcript of an episode of Public Address Science which was originally broadcast on Radio Live, 25th August 2007, 5 pm - 6 pm.

You can listen to the original audio version of the programme by clicking on the 'Play the audio for this post' link at the top of this page or the 'Audio' button at the bottom of this page.

Background:

[Sound of thunderstorm]

Voiceover:

Unless we're experiencing a thunder and lightning storm like this one -- where colossal amounts of electricity are discharged into the air above us -- the subject of energy is something that most of us rarely think about. In our normal day-to-day lives, we simply assume that, for example, energy in the form of petrol will always be there to fill the fuel tank in our cars, and that energy in the form of electricity will flow from the wall-sockets in our houses at the flick of a switch.

But over the next few months I'm going to examine the subject of energy in a lot more detail. Where it comes from, how it's used, and -- at the risk of sounding overdramatic -- its vital importance to civilization as we know it.

I'll be looking at the ways in which energy has transformed human life throughout history from the Palaeolithic to the space age -- and I'll be talking to energy economists and international energy experts about the importance of energy to global society.

Then in the last half of the series, I'll narrow my focus to New Zealand. I'll look at our energy resources and consumption, and I'll talk to New Zealanders in the energy sector as well as our government policy makers. Finally, I'll attempt to look into the future, and find out what we should be doing as a country to meet the energy challenges of the next few decades.

Background:

[Wind over high-tension power lines]

Voiceover:

When you really think about it, it's humankind's ability to capture and harness energy -- over and above the simple food energy that all organisms obtain -- that actually makes human beings what we are.

Our ability to capture this non-food energy impinges upon

all aspects of our existence. For example, captured energy was required to manufacture every article of clothing that you're wearing right now. Captured energy was required to fertilize, harvest, transport, or refrigerate virtually every item of food that you've ever tasted. And captured energy was required to manufacture every implement or tool that you've ever used: from knives and forks, to screwdrivers, to alarm clocks, to the roof over your head.

Captured energy is, quite literally, the lifeblood of civilization: without energy the cars and buses don't run, water doesn't come out of the taps, and our high-tech hospitals become nothing more than unrefrigerated mortuaries... without captured energy humankind is back in the stone-age. In fact, we're back in the really bad bit of the stone age -- the bit before fire was even discovered.

But what exactly is energy?

It's actually surprisingly hard to define. Before we think about energy, we've got to talk about something called 'work'.

Background:

[Sound of block and tackle]

Voiceover:

I'm using an old-fashioned block-and-tackle to lift some sacks of cement about two metres up into the air. In the normal sense of the word, I'm finding it to be hard work. But the word 'work' also has a specialized scientific definition. In a scientific sense, work is performed when a force is applied to an object -- and that object undergoes movement. This 'scientific' work, measured in joules, is simply the force acting on the object multiplied by the amount of displacement that it causes.

In my particular case, I'm applying a force to the sacks of cement (via a rope) in order to overcome the earth's gravitational pull. The mass of the cement is 100 kilograms, and therefore it weighs about 1,000 newtons under the earth's gravitational field. So when my arms

apply 1,000 newtons of force to lift the sacks of cement two metres into the air, then I've performed 2,000 joules of work (i.e. 1,000 newtons x 2 metres = 2,000 joules).

Now work is important because it's the way we see what energy actually does. Energy itself is rather intangible, and so -- in scientific terms -- energy is most often defined simply as:

Energy is the ability to do work.

So let's get back to my sacks of cement. If a normal person were to look at me, they would simply see a sweaty geezer hauling on a rope. But to the eyes of a scientist, I'm doing 2000 joules of work in lifting the sacks of cement -- which tells them that 2,000 joules of energy must be flowing in a Harry-Potter-like manner from my fingers to the rope.

Background:

[Sound of wind turbine]

Voiceover:

Of course, energy can take many different forms. It could, for example, be kinetic energy contained in a quantity of air, which moves rapidly through a wind turbine like this one, and performs work on the rotor blades.

Background:

[Sound of water running down the spillway of a dam]

Voiceover:

Or it could be the gravitational potential energy contained in a quantity of water sitting in a dam, which can be allowed to fall under the earth's gravity, and perform work on a water-turbine.

Background:

[Sound of car engine]

Voiceover:

Or it could be the chemical energy contained in a fuel such as petrol, which is converted to thermal energy (or heat) when it burns and expands the air inside a cylinder, so that work is performed on a piston.

Background:

[Sound of electric motor]

Voiceover:

Or it could even be electrical energy, which flows through coils to induce a magnetic field, and performs work on the rotor of an electric motor.

But in terms of the way we generally use energy in society, it's not just quantity that's important, but also the rate with which energy can be turned into work. The amount of work done per unit time is called power, and it's measured in watts -- where one watt is equal to one joule of work done every second.

And to prove that no effort has been spared in bringing you this programme, I've just climbed all the way up the staircase in Auckland's Skytower building. Along the way I've been measuring both my work and my power output.

It's taken me 14 minutes to raise my 85 kilogram body up 234 vertical metres of staircase, which equates to 195,000 joules of work performed. I'm feeling really quite tired, but that's only about the same amount of energy as contained in just seven millilitres of petrol (around one cent's worth at current prices).

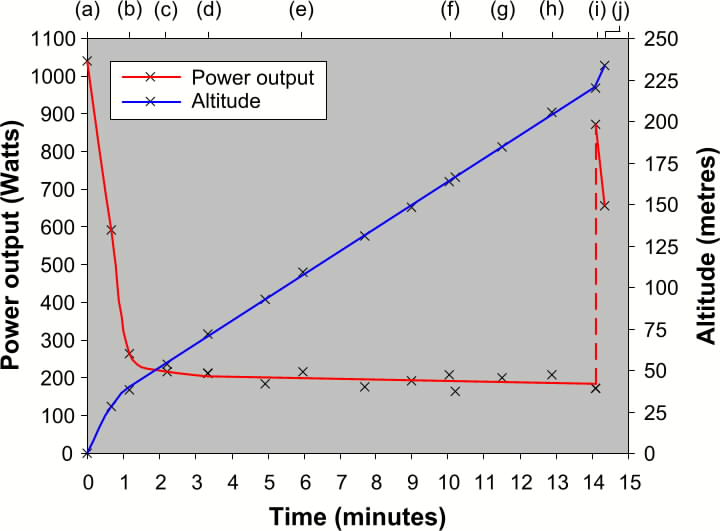

I started my climb running up the stairs at the bottom with a power output of just over 1,000 watts (1,000 joules every second). But I just finished my climb at a slow walk and a power output of only 200 watts. My average power output during the whole climb was a mere 227 watts.

Above: Work and power output when climbing Skytower (a)–(b) running up stairs, (b)–(i) walking up stairs, (i)–(j) running up last three flights of stairs, (c) breathing heavily, (d) legs beginning to feel tired, (e) beginning to perspire heavily, (f) perspiration dripping from chin, (g) legs extremely tired and perspiration dripping from end of nose, (h) legs starting to hurt, (i) shirt soaked with perspiration, (j) reach the top of the stairs (63rd floor) [click to see a larger image].

To put that into perspective, the power output of a 50 cc motor scooter is around 2,000 watts, the power output of a medium-sized car is around 100,000 watts, and the power output of the engines on a Boeing 747-400 aircraft is more than 140,000,000 watts.

Background:

[Sound of Boeing 747-400 aircraft]

[Sound of sticks rubbing together]

Voiceover:

Those numbers are rather overwhelming, but now that we have an understanding of basic

concepts such as work and power we can begin to discuss the subject of energy in more depth.

I'm making a start by using my relatively meagre human power output to make fire -- literally by rubbing two sticks together. And I'm not having much luck, although I've just managed to get a bit of smoke.

But more on that next week: when we go back to the dawn of time, and look at the way energy has been used throughout the course of human history.

Background:

[Sound of sticks rubbing together]

- Read about energy, work, and power at HyperPhysics.